Software- aided Pattern Making, a Blessing for the Plush Toys Industry

The tentacles of technology

rambling through the beckoning trail of twenty-first century, we are enthralled by technologies and innovations alongside. We have never seen a trail as bountiful as this, eager to discover more technological feats beneath the mist.Indeed, we are now in an era of novel technologies. An invisible monster is spreading over its tentacles everywhere, trying to grab everything to make it digitized. Since when everyone lives with a smartphone and since when purchasing things online is no longer fresh...As a custom stuffed animal manufacturer, we perceive the tentacle by seeing changes concerning how we make a pattern.

What is plush pattern-making?

Plush pattern-making is a core and integral procedure of making a custom plushie. Every stuffed animal you seen--whether in a promotional campaign for attracting customers or paled in a claw machine--all comes from a pattern. If you want to turn one of your drawings into a real plush, you may turn to Toyseei or try to do it by yourself, but both of us would flounder did we not have a plush pattern first. It builds a bridge between an idea and the actual custom plush toy, makes the idea more deliverable and ensures that the custom stuffed animal is more agreeable.

Software serving in pattern-making

In the light of the importance of pattern-making process, a number of relevant software that can be helpful comes out with no surprise. And tech companies have mounted their emphases on developing a competitive plush pattern-making software. The functional ones can generate a favourable financial benefits for them.

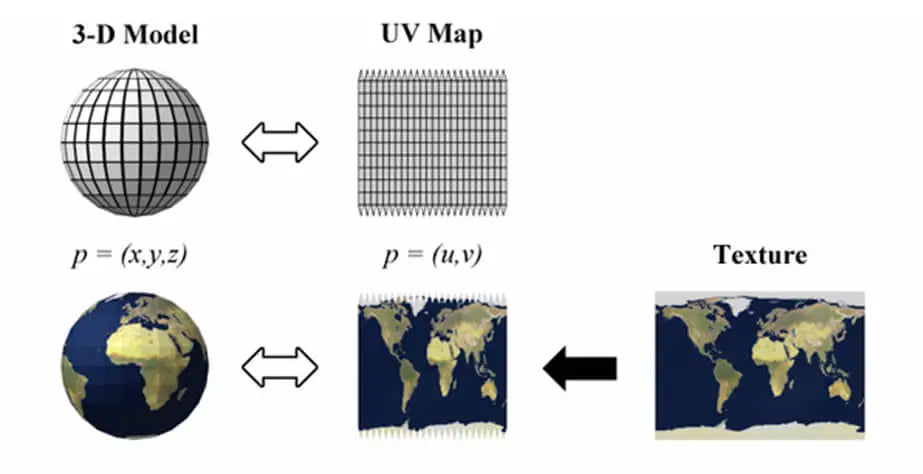

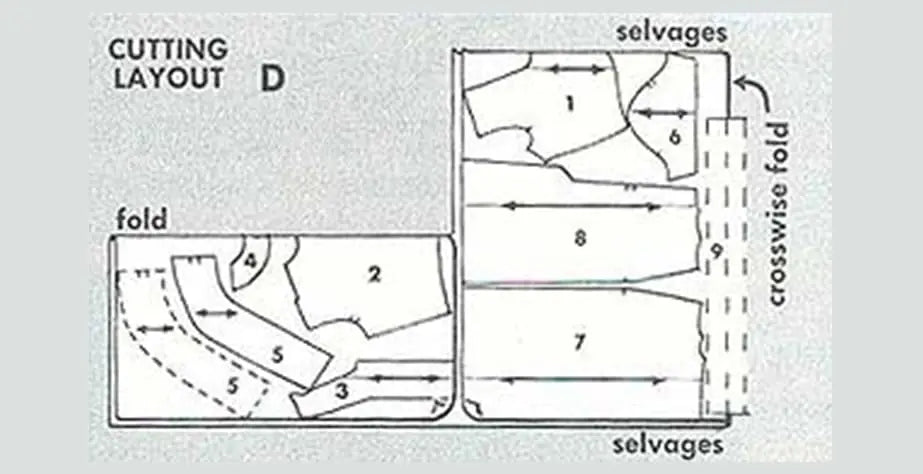

So far, software serving in pattern-making is classified into three categories: 3D Model Building Software(like EasyToy, Blender), UV-mapping* Software(like PatternImage), Cutting Optimization Software (like Presto, Secant), all of which play an independent role during the process of making a pattern of a custom plush.

Here are the procedures of making a plush pattern through software: First, delineate a 3D image modeled on your draft. Second, UV-map the image from 3D to 2D punctiliously, and outline every piece of a pattern. Third, determine how you cut the fiber as each piece needs different colour and materials. Coincidentally, there are three categories of software to assist these three procedures respectively.

*UV-mapping: In plush toy Industry, UV mapping is a process of projecting a 3D model's surface to a 2D image for texture mapping. The two letter UV stand for the axes of the 2D texture respectively as X", "Y", and "Z" are already used to denote the axes of a 3D object. As for pattern makers, UV-mapping is nothing less than a bedrock of devising a satisfactory plush pattern. Using this method promises to give your plush pattern more precision and weaken the necessity of visualization.

Examples of software-aided plush pattern-making in China

Many plush toy manufacturers in China use EasyToy to build a 3D Model. EasyToy is relatively more easily to operate by virtue of its neat sketching interface. Pattern makers upload the image of a draft, then this software will scan it thoroughly and produce a rough holographic model. Just wait for a while, all details will be shown on the model. They can drag their mouses to scrutinize this three-dimensional model from whatever angel we want, and making well-timed adjustment if needed.

Subsequent to building a 3D Model, pattern makers need to unwrap the 3D model into a 2D picture so as to make a plush pattern with detailed pieces.

Following the completion of UV-mapping is to design an optimal cutting layout, the home stretch of making a plush pattern. As we know, a plush pattern is composed of many pieces, and these pieces have different requirements on which colour the fiber should use and which material we should choose for the fiber. Accordingly, it is crucial to fully utilize each kind of fibers in order to save costs and promote efficiency. This kind of software is endowed with the ability of providing pattern makers with an optimal printing layout automatically and instantaneously, after you uploading the detailed information of your plush pattern. Presto is one of the software welcomed by Plush toy manufacturers in China. In addition, Presto has an another function that it can carry out an evaluation on the whole cost.

As is cited in China’s Toy Business Development Forum in 2020, newly-emerged technologies is making a difference in the design, production and marketing of toys, and they are projected to have far-reaching implications in the future. Especially for some businesses where their toys are of high specification or served as customized products, such as stuffed animals, using software to aid their productions is already a common practice.

Traditional manual plush pattern-making

Although we have introduced how to make a plush pattern through a computer , the traditional way cannot be overlooked. The traditional plushie pattern-making techniques consists of three procedures. First, pattern makers form an image in their minds where the intended plush toy is unwrapped on a two-dimensional basis. Second, they need to compartmentalize the flattened image into pieces(usually using visualization). Third, they draw the outlines of those pieces on a paper or a Kraft. It may take a couple of hours to create an acceptable plush pattern as calculating numerous lengths, widths and angels is a strenuous work.

Probably giving you a sense that this is easy-peasy once you read this brief introduction, upon a closer look, making a plush pattern manually is actually a demanding and exclusive technique.

If you are an utter outsider, you are very likely to find it challenging to doing such a thorny thing just in your mind. And when it comes to visual compartmentalization, lack of imagination, relentless modification will sap your energy and motivation. Even if these two things are not problematic for you, determining outline would be a stumbling stone unless you are a drawing gurus, because even a peccadillo can also ruin your final prototype.

Why it is exclusive? As a derivative of textile industry, this technique is only available to acquire in a plant or workshop. If you are aspired to learn it in your university, the curriculum in your school’s repertoire may not live up to your expectation. In China, students can only develop a grounding of this technique, like improving their drawings and paintings, acquainting themselves with the attributes of various fibers and getting some insights of aesthetics. With these pieces of knowledge, they are then qualified to dig into how to make a pattern manually in a factory. In other words, only the person who is ready to join the line of plush toy manufacturing can access this technique.

Pattern makers are also required to have a sterling sense of space and prominent abstract thinking. You cannot judge a pattern maker by how eloquent he or she is in the job interview. Pattern makers use their hands to articulate. Giving them a picture and let them make their plush patterns in a certain period of time is enough to put them at their own paces.

Trials, errors, and taxing training of the traditional method

Expertise pertaining to manual plush pattern-making is promised by trails and errors, and the training involved has a long time span. As a common practice, factories usually adopt mentorship as their ways to impart this technique. Pattern-making veterans often hire job seekers with more art knowledge and ambition as their apprentices.

Customarily, the training consists of three stages. The first stage is named as novice stage. Apprentices are required to understand how the process really works and develop their abilities of visualization. Some use the approach of so-called trials and errors where they just try to design a plush pattern, see how unpleasant the work they did is and target problems to ensure that they won’t reoccur next time. This is one of the best ways to expose their underlying shortcomings and help them recognize the gap between the preliminary and the proficient. Furthermore, when their deficient works are presented, they can’t feel no compunction of doing an imperfect job as an apprentice. In turn, the sense of guilt will drive them to be more dedicated.

There is an another approach some veterans advocate to help them go through novice stage smoothly--let apprentices to disassembly a number of plush toys. This is the most direct and effective way to help them knows the role plush pattern plays in forming a stuffed animal. After cutting them through the sewing seam, every pattern of this plush will be flattened on a stand. Pattern-making veterans regard this way as “shattering the barrier of space” and providing the bedrock of being an adroit visualizer.

After striding over the threshold, apprentices come to the second stage: practice stage. Just as what it was named, the fundamental task in this stage is to practice as much as possible until you are well adept at plush pattern-making. During the first stage within the training, a mentor prioritizes quality, whereas during the second stage, he or she prioritizes speed and efficiency. Maybe you can make a exquisite plush pattern, but you cannot take too much time. Long waiting time would delay the whole production process, not least the customized plushies, which waters down the consuming desires of customers. A pragmatic way to gain efficiency is never put a brake on your practising while doing a self-examination after one practice is finished.

The third stage is called professional stage, and this stage may take ages. In plush toys industry, there isn’t an authoritative standard to define a professional manual pattern maker. However, they share common features. A professional can make a plush pattern in a shorter period of time but not at the expense of quality at the altar of efficiency, and they can grasp the spirit of a draft. The time of transforming from a common to a professional somehow depends on one’s talent, and during this period, your improvement largely rest on your personal efforts, and mentors usually just give them some constructive suggestions.

Different from others, when a professional manual pattern-maker is assigned to make a plush pattern, the first thing he or she is gonna do is to grasp the main characteristics of the draft and compare them with a cornucopia of plushie patterns he made in the past, rather than going through the three routine procedures. The works they finished in previous practices served as a powerful arsenal--all bullets are at their disposal, what they need to do is only to adjust and modify a similar plush pattern, which explains their high efficiencies.

The cost of cultivating a manual pattern-maker is far bigger than cultivating a counterpart who uses computer to do it. The mentorship and the three phase involved substantially elevate the cost of time and money. It may take 2 years to offset the cost to cultivate a manual pattern maker? So what if that apprentice resigns before staying in the factory for two years. In that case, the weaknesses of hiring new manual pattern-maker is self-evident: high cost, high risks, unfavourable ROI.

Prominence

With computer becoming more of ubiquity, software-aided pattern making is no longer rocket science in plush manufacturing industry. Having received a training of about three months, one with rudimentary computer knowledge could get the hang of using software to make a plush pattern. Currently, the majority of plush companies have at least one or two pattern makers capable of performing this technique.

When we make a plush pattern on a computer, 3D Model Building, as a step determining the outline of a plush toy, plays a guiding role throughout the whole process. It provides pattern makers, production inspectors and customers with a valuable reference*transcending time. Moreover, the usage of 3D Model building improves and expedites the pattern-making process.

A pattern made by software like PatternImage gives its maker more convenience. In the past, if patter maker needs to adjust one piece of a custom plush toy’s pattern, he or she would do an arduous work, because pieces of the pattern are connected with one another, which means they cannot just adjust one piece and ignore others. Instead, they shall recalculate the length, width and angels of all pieces to ensure the revised custom plush is still meshing with the original draft. However, with software they don’t need to take extra time when they just need to adjust one piece of a whole plush pattern--No sooner had you reset the new shape and figure of that piece than software automatically modified other pieces to follow your adjustment.

Moreover, a plush pattern made by software boasts more precision than a plush pattern made by manual efforts. When establishing a pattern manually, pattern makers sometimes use their gut feelings to handle some thorny details of the draft, which spells imperfection. In contrast, the majority of software uses their algorithms to deal with these details, eliminating possible errors.

In the past, it is painstaking to manually figure out an optimal cutting layout. Pattern makers would rather relinquish the chance of lessening the cost than doing a complicated calculation. But now, with software, pattern makers won’t be torn between whether they should bite the bullet to manually find the optimal printing pattern of the bespoken plush.

*Time-transcending reference:When it comes to traditional manual plush pattern-making, not until we had finished the cotton stuffing did we got a demonstration of what the intended plush toy really looks like. Here is a felicitous simile: it’s like you are solely washing a cloth with obstinate stains in a pitch-dark room. You can’t resist your temptation to cast doubt on whether it is clean enough, but you have nothing to do. Only when you are out of the room can you see the laundry job you did. There would be two things bothering you. The first is that you are prone to a sense of insecurity, which would vitiate your morale as each strand of efforts you made fall to be reflected instantaneously. Assuming that you wash the cloth for extended periods of time, even if you are a proficient laundry man, or you have a passion for washing cloth, that sense of insecurity still has a negative impact on your mental state and working efficiency. The second is that you might invest unnecessary efforts in your washing. Without a categorical assurance that your cloth is already clean, you have to continue to wash it until your washing time is far fair long, in case you should inadvertently miss some parts of stains. Actually, your concern is superfluous but difficult to skip. Pitch-darkness, an avatar of uncertainty, did ramp up the incidence of hypochondria, increasing your time cost.

But now, with 3D Model Building, things are changing dramatically. The pitch-darkness no longer exist, and we are making plush patterns under balmy sunlight. As soon as pattern makers establish the 3D model, they can get a lucid demonstration of the final product. This demonstration equips them with an ability of screening problems earlier. Traditionally, we ask customers’ opinion only after when the cotton stuffing procedure is done, which means we need to get an actual prototype. But now, we can secure their opinions by offering them a 3D model. This nips problems in the bud and therefore saves fixing time substantially.

Current weaknesses

Although we spill much ink on the merits of three plush pattern-making software, software-aided plush pattern-making is not something without blemish. Software that can be served for making a plush pattern is still in its infancy, which means it has much room for improvement. Its analytical ability and emotional perception are not as keen as an actual human, which means this kind of software is yet to reach AI level.

If you let some 3D Building software to scan a draft where an adorable mascot laughs with grinning teeth, probably they could only recognize the face per se, and it fails to get the sense of joviality. Once you get a glimpse of the face on the 3D model it established, it may give you an unnatural feeling. Granted that this software could simulate shapes and details perfectly, but it doesn’t acquit itself admirably in simulating emotions. Asking a plush pattern maker manually make a 3D model of a customized plush may take an extra time of around 3 or 4 hours. Nevertheless, even a layman can heed that the laughing face manually made is natural and accommodating than the face automatically made.

Also, granted that some UV-mapping software can smoothly turn a whole 3D model into a 2D pattern, but they sometimes don’t take cotton stuffing process into consideration. According to the conventional wisdom in plush manufacturing industry, it is not quite often that the shape of final prototype is exactly the same as the 3D model, and some parts of the final custom plush may become flattened or dilated during the cotton stuffing process.

Also, granted that some UV-mapping software can smoothly turn a whole 3D model into a 2D pattern, but they sometimes don’t take cotton stuffing process into consideration. According to the conventional wisdom in plush manufacturing industry, it is not quite often that the shape of final prototype is exactly the same as the 3D model, and some parts of the final custom plush may become flattened or dilated during the cotton stuffing process.

Yet, when manually designing a plush pattern, pattern makers always take this factor into account and make some modifications on the figures of a number of pieces. For the parts easily fall prey to over-stuffing, they may extend their lengths and widths, and for the parts which easily become flat, they will ameliorate these parts more blunt to increase the influx of cotton. However, there is a premise in the default algorithms of software that the intended custom plush is destined to be as same as the 3D model in the computer, which means if we trust this software indiscriminately, we possibly encounter imperfections.

The current issue of cutting optimization software is that when it comes to bulk production, it overestimates the ability of fiber-cutting machine. Undoubtedly, software has an incomparable prowess on designing an optimal cutting layout of a custom plushie. Its algorithm only center its efforts on design, and disregard whether this layout is plausible in terms of the fiber-cutting machine. Occasionally, a number of curves on the presented layout are odd and the curves are too close to each other. If we upload it onto the cutting machine, the system risks crashing because it cannot handle this level of intricacy. Even if the machine can recognize, frequently twisting and turning the blade may have a deleterious effect on machine’s durability. In that case, the pursuit of an optimal cutting layout is counter-productive. Although designing a cutting layout of a tailored plush toy without software cannot minimize the cost, it is more practical and beneficial in the long run.

Craftsmanship

Traditionally, plush toys were generally made through manual works. In 1880, Steiff, a company based on Germany, launched a stuffed elephant, which is the first plush toy in human’s history. Steiff was founded by Matgarete Steiff, who was paralyzed by polio in her childhood. But then she realized that she has a gift for sewing and weaving, coming up an idea of making a plush toy later on. With her ingenious design and unwavering perseverance, in 1902, she successfully turned her idea into a business. Over the following century, plushies has become an embodiment of craftsmanship.

Now, the software-aided plush pattern-making is making a difference on the old manual pattern-making. Perhaps there are only a few plush toys manufacturers ruling out the strengths of software-aided pattern making and shunning any changing of their pattern-making process. The designing of a plushie pattern is moving towards a callous process, and the manual plushie pattern-making is set to be less treasured in view of its low efficiency and high cultivating cost. However, software-aided pattern-making of stuffed animals has nothing to do with craftsmanship, and some stuffed toys companies value this spirit as a kind of intangible industry heritage. In that case, putting this technique on a pedestal is not completely wise, and how to make this craftsmanship well-preserved is a question for us.

Unsettled but promising future

Despite that software-aided plush pattern making technology brings prodigious boons to the plush manufacturing industry, the answer to whether it is a surefire winner in the future is still shrouded in uncertainty. But there is one thing we can envisage: software will become more advanced and serve the plush pattern-making process better. Perhaps the problems that software’s designers rack their minds to solve would become a piece of cake in the future. But for the fellows engaging in this line of business, we should always be vigilant against it--trusting software completely is dangerous, and resisting the trend in the digitized society is also put yourself in jeopardy amid competitions. It is advisable that pattern makers embrace and keep abreast with the software-aided pattern-making technology. Yet, software is nothing more than a representation of human intelligence, pattern maker should hold a keen eye to detect problems and fix them timely, let software facilitate instead of controlling plush pattern-making.